Geosecure

Construction And Mining

Geosecure understands the unique challenges of the construction and mining industry. Our tailored solutions ensure your fleet is safe, productive, and cost-efficient, no matter the conditions. Trust Geosecure to keep your operations running smoothly and effectively.

Cut Costs

Lower fuel consumption by reducing excessive idling and optimising routes with trip history reports that offer actionable insights for future savings.

Minimise insurance costs with GPS tracking and dashcams, monitoring driver behaviour and ensuring compliance with speed, break, and zone rules.

Automate maintenance scheduling using odometer readings and SMU hours, predicting issues before they lead to breakdowns, keeping your fleet in top condition.

Prioritise Safety

Respond swiftly, no matter the location, with Geotab's GPS tracking and satellite modems.

Equip your fleet with essential safety features like in-vehicle duress alarms and man-down safety pendants for isolated workers.

Automated GPS alerts with rollover detection notify operational teams and emergency services when assistance is required, ensuring a rapid response in critical situations.

Increase Productivity

Boost efficiency by delivering real-time driver training with Praiso, reducing the need for costly, time-consuming classroom sessions.

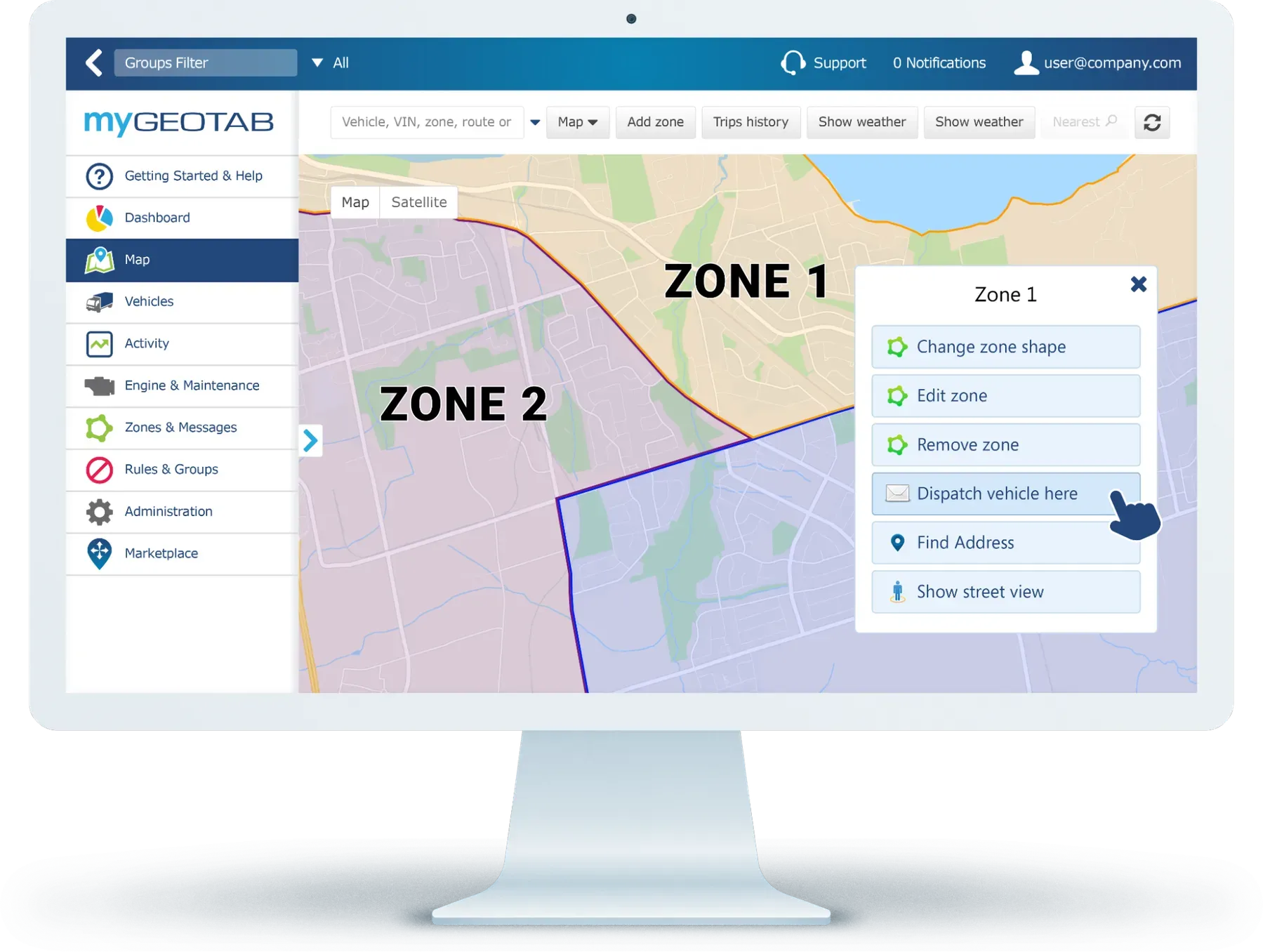

Monitor driving behaviours instantly, receiving alerts for excessive idling, speeding, and route deviations.

GPS tracking, telematics, and route optimisation ensure maximum job time, resource allocation, Geofencing, and vehicle monitoring to enhance productivity on every shift.

Learn more about our products

Discover how our telematics solutions can transform your fleet management - streamline operations, reduce costs, and make data-driven decisions.

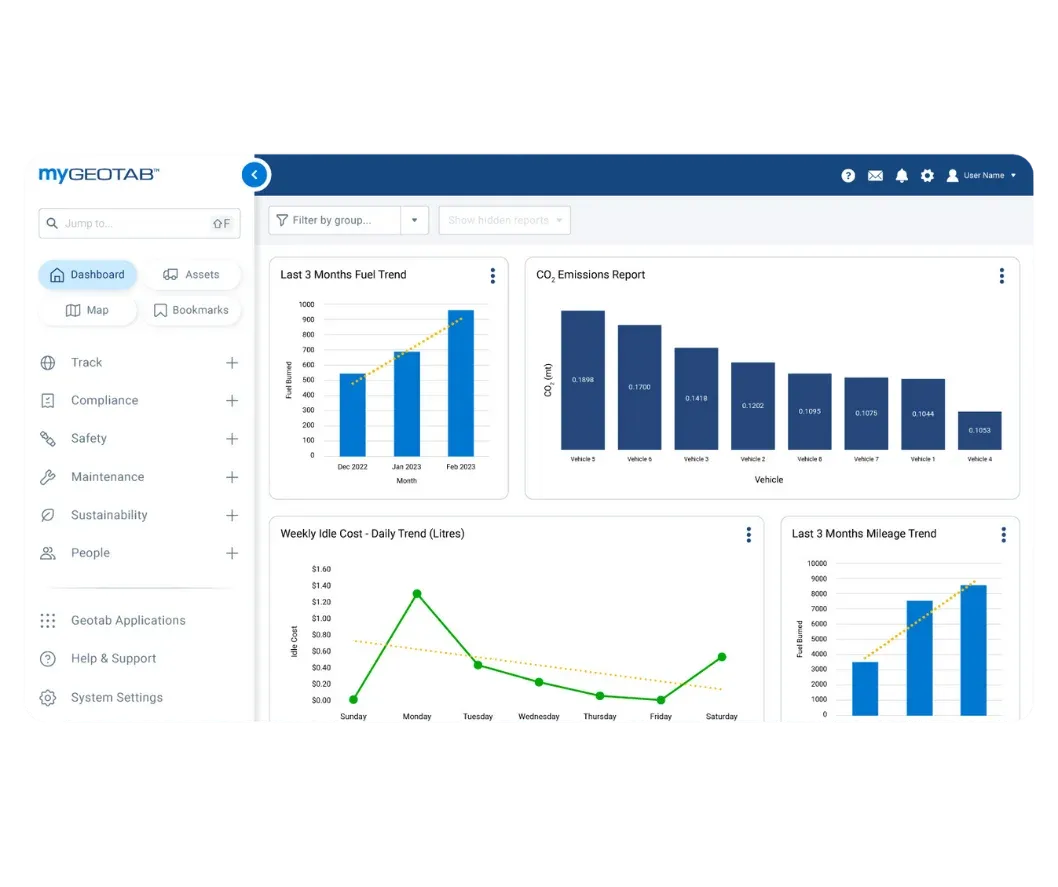

Achieve Holistic Fleet Oversight with Telematics Monitoring Application

Comprehensive fleet monitoring is crucial for service and specialty trades. Geosecure's Telematics Monitoring Application (TMA) offers detailed oversight to enhance your operations.

- Comprehensive Monitoring: Geosecure offers a Telematics Monitoring Application (TMA) for holistic fleet oversight.

- Accreditations: Includes fatigue, maintenance, and mass accreditation to ensure full compliance.

- Real-time Insights: Monitor and manage fleet operations with precision.

Maximise Financial Efficiency with Fuel Tax Credits

Optimise your fuel tax credits and ensure compliance with Australian law through our expert partnerships.Optimise your fuel tax credits and ensure compliance with Australian law through our expert partnerships.

- Expert Partnerships: Geosecure collaborates with KPMG and Ryan for Tax Fuel Credits (FTC).

- Maximise Credits: KPMG's data-driven approach and Ryan's global tax expertise ensure optimal FTC outcomes.

- Efficient Management: Leverage advanced data science and automation for reliable fuel tax management.

Simplify Compliance with Electronic Work Diary

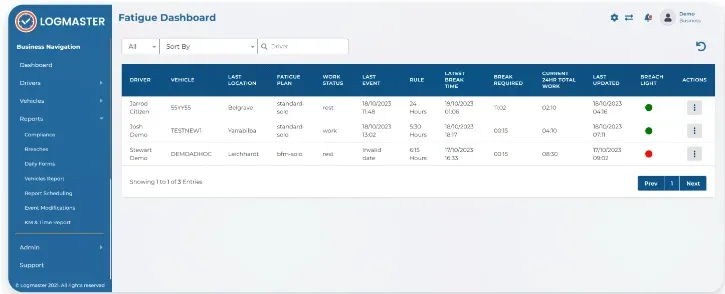

To further streamline operations and ensure compliance with Australian regulations, Geosecure partners with Logmaster to offer advanced Electronic Work Diary (EWD) solutions.

- Simplify Compliance: Geosecure partners with Logmaster to provide Electronic Work Diary (EWD).

- Accurate Records: Ensure professional drivers maintain accurate records effortlessly.

- Enhanced Compliance: Benefit from Logmaster's leading electronic work diary technology.

Learn More Via Our Interactive Solution Builder

Geosecure recognises the demands of the service and specialty trades industry. Our customised fleet management solutions enhance safety, boost productivity, and reduce costs in all conditions. Trust Geosecure to keep your tradespeople on the move efficiently.